Every company in the manufacturing industry needs reliable and cost-effective capabilities to support production processes. Here at LCS Company, we understand that and have tailored our services to meet these needs better than anyone else in the market.

With years of experience, we have become specialists in motor lamination manufacturing and metal stampings while excelling in several other capabilities, such as custom bracketry and metal clamps, miniature and micro stampings, custom shims, and custom washers.

We pride ourselves in creating solutions that meet your unique needs. Let us show why we are the go-to choice for quality stamped metal component parts.

Custom Electric Motor Laminations

Electric motor laminations play a crucial role in the performance and reliability of electric motors. They are made from thin sheets of Electrical Steel, Cobalt, and Nickel alloys, creating durable lamination stacks used to construct motor windings. The design and construction of these laminations are critical, as it affects the overall efficiency, torque output, size, and weight of the finished motor.

At LCS Company, we specialize in custom electric motor lamination services to meet our customers’ requirements. We understand that proper design and construction are essential for optimal performance, so we use state-of-the-art equipment and techniques to ensure that each lamination is accurately made according to customer specifications.

With a wide range of materials available, our team can create laminations with various shapes and sizes based on desired performance requirements.

Custom Metal Stamping

Custom metal stamping is a manufacturing process involving dies and specialized machines to mass-produce parts with precise shapes out of sheet metal. The process starts with blanking, which consists in cutting a flat metal into the desired shape and size.

This shape is then formed using special tools called dies to create the final product. Custom metal stamping can be used for various applications, such as:

- Automotive components

- Aerospace components

- Medical devices

- Electronic devices

- Hardware items

- Other applications where precision and repeatability are vital factors

At its core, custom metal stamping is an efficient and cost-effective method for producing high volumes of products quickly and accurately. It’s also very versatile in making parts in various shapes and sizes. Additionally, it is one of the most cost-effective manufacturing processes available since it requires minimal setup and workpiece preparation time.

It’s important to consider a few factors when deciding whether custom metal stamping is the best method for producing your desired products. This includes:

- Material selection

- Tool design

- Production volume

- The complexity of every component

- Accuracy requirements

- Surface finish specifications

It’s also worth noting that custom metal stamping can be used with different types of metals, such as steel, aluminum, brass, bronze, copper, and titanium. Depending on the application, you might need a specific type of metal to achieve the desired results.

At LCS Company, we specialize in custom metal stamping services and have years of experience producing high-quality parts quickly and cost-effectively. Our team of experienced engineers and technicians can help you design the tools necessary for your metal stamping requirements and walk you through every step of the production process.

From material selection to tool design, we ensure that all aspects of the manufacturing process are considered when producing your desired parts or components.

Custom Bracketry and Clamps

Bracketry and metal clamps are essential to many construction projects, from furniture building to bridge repair. Brackets are formed component pieces of metal that can support two pieces of material at varying angles, while metal clamps provide strength and stability to joints by applying pressure over a defined area.

When choosing the type of bracketry and clamps for your project, you must consider the weight that will be placed on them and the amount of movement between two materials when under load. Heavy-duty brackets that use bolts or screws should be chosen for heavier load where less flexibility is needed.

At the same time, lighter designs with more flexible connection points may work better for smaller items with some expected movement. Additionally, if you are connecting two dissimilar materials, choose brackets that will not rust from contact with one another.

When using clamps for joinery, it is important to understand the types of force generated by them. Different clamp designs can generate different amounts of pressure with various joint configurations. A wide variety available allows you to select the best solution for your project and minimize unwanted movement or sliding during assembly or operation.

At LCS Company, we have experience with many types of brackets and clamps for various projects. Our team can advise on the best clamp solution for your project, so you can be sure your assemblies will remain stable and secure. With years in the industry, LCS is your go-to source for reliable tools and hardware to complete any job.

Micro and Miniature Stampings

Miniature and Micro Stampings are complex metal components that require exact engineering processes. When it comes to stamping, a variety of materials can be used to create custom parts and components. The most commonly used materials include steel, aluminum, brass, copper, and nickel silver. Each material has unique properties and characteristics that make it well-suited for specific applications and industries.

Stamping is a cost-effective way to manufacture small parts for:

- Medical instruments

- Automotive parts

- Aerospace components

- Electronics components

The precision of these parts allows them to be used in various applications where exact dimensions are essential.

At LCS Company, we produce high-quality micro and miniature stampings for any application. We can create highly intricate parts from a wide range of materials with our experienced engineers, who use advanced technology to ensure all parts are manufactured with tight tolerances and exact dimensions.

Custom Shims and Washers

Shims and washers are the most commonly used fasteners. Shims are thin pieces of metal or plastic that may be placed between two objects to create a gap for adjustment purposes.

At the same time, washers help to distribute the load across a wider surface area or to provide insulation from electrical currents. Both types of fasteners can be used in construction, engineering, and manufacturing projects.

At LCS Company, we provide custom shims and custom washers to meet the specific needs of our clients. We can offer specific materials to meet your specifications, so you can be sure you are getting the best possible product for the job.

Full In-House Tooling Capabilities

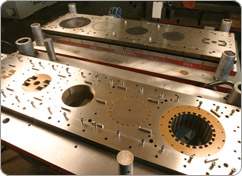

Metal stampers with full In-House Tooling Capabilities are essential for businesses looking to streamline and control the entire manufacturing process. With our experienced team of designers and engineers, we can provide the best possible solutions for any project using various CAD/CAM services.

Our team provides efficient and cost-effective strategies to ensure you get the best results for your tooling needs. Additionally, our design process ensures that all our products meet or exceed industry standards regarding quality control and precision machining.

With our state-of-the-art technology and machinery, we are confident we can provide you with the best tools and services to optimize your manufacturing processes.

Excellent manufacturing capabilities at LCS Company

Our commitment to innovative solutions and outstanding customer service sets us apart from all other companies. We understand our client’s needs and take great pride in timely delivering top-notch products. Our team of professionals has the experience, skillset, and knowledge to handle any task or assignment.

Whether you are looking for custom electric motor laminations, metal stamping, or other manufacturing capabilities for different parts requested, we have precisely what you need! With our extensive portfolio and superior services, you won’t be disappointed. Contact us today if you want quality manufacturing capabilities for virtually any product or part you can imagine.