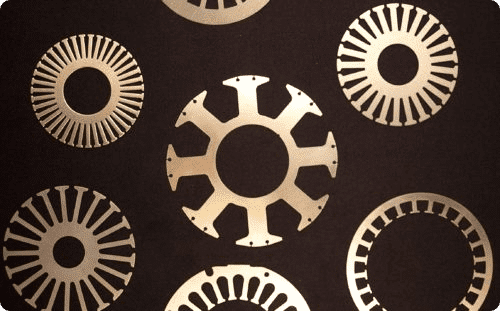

LCS Company is a leading manufacturer of stamped motor laminations, from prototypes to large production runs. We make our rotor and stator laminations from highly conductive metals and high-performance nonmetals with tight tolerances. Learn more about motor laminations and how they contribute to motor performance.

What Are Motor Laminations?

What Are Motor Laminations?

Motor laminations are crucial components of a motor’s stator and rotor. They are made of thin sheets of material that are welded, stacked, or otherwise bonded together. Unlike solid pieces, this design minimizes eddy current losses.

Materials Used in Motor Laminations

Here is a detailed look at the materials we use to make motor laminations.

Our Motor Lamination Stamping Capabilities

At LCS Company, we manufacture laminations that meet strict industry regulations and require certifications for manufacturing processes, raw materials, and heat treating. We produce electrical laminations and lamination segments with ½-inch to 24-inch diameters using our punches, which range from 3 to 330 tons.

Our facility’s automation capabilities can regularly produce a few thousand to a few million units per order. To meet our customers’ requirements, we usually process cobalt and nickel alloys, silicon steels, and cold-rolled motor laminations. We also use nonmetal lamination materials such as Delrin, fiberglass, Nomex, PTFE, and rubber.

We build and maintain in-house progressive and compound tooling technologies to ensure products meet exact specifications. LCS also houses laser cutting equipment for small batches and prototyping. Using any motor lamination material we’ve discussed here, LCS Company can create the perfect laminations for your needs. Request a quote today to start your custom order.

Request a quote